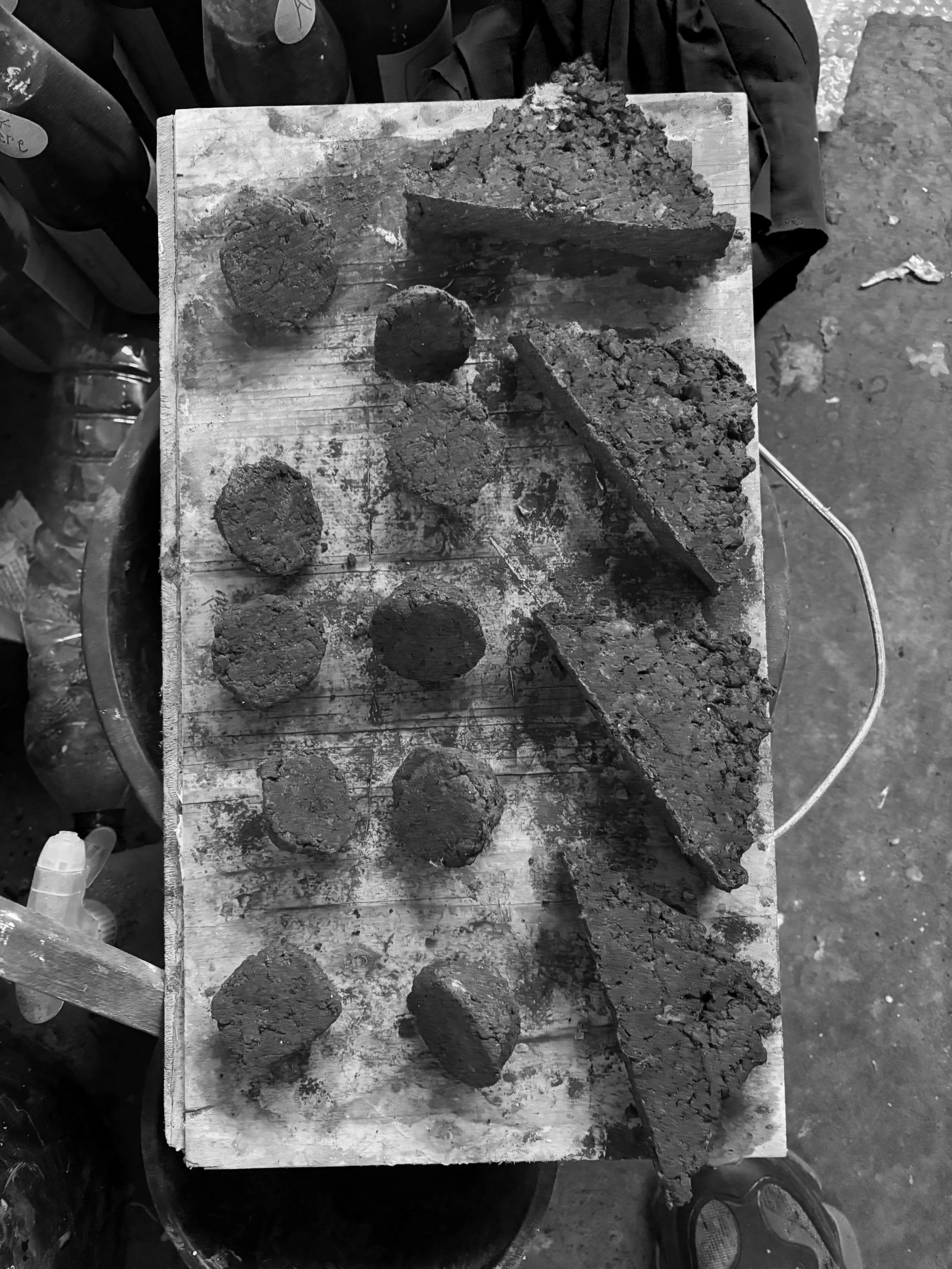

An experimental composite

made of pellet ash and old news.

description

Components:

Pellet ash: a byproduct of biomass heating systems that acts as a mineral filler.

Newspaper pulp: cellulose fibers with water, reinforcing and binding the structure.

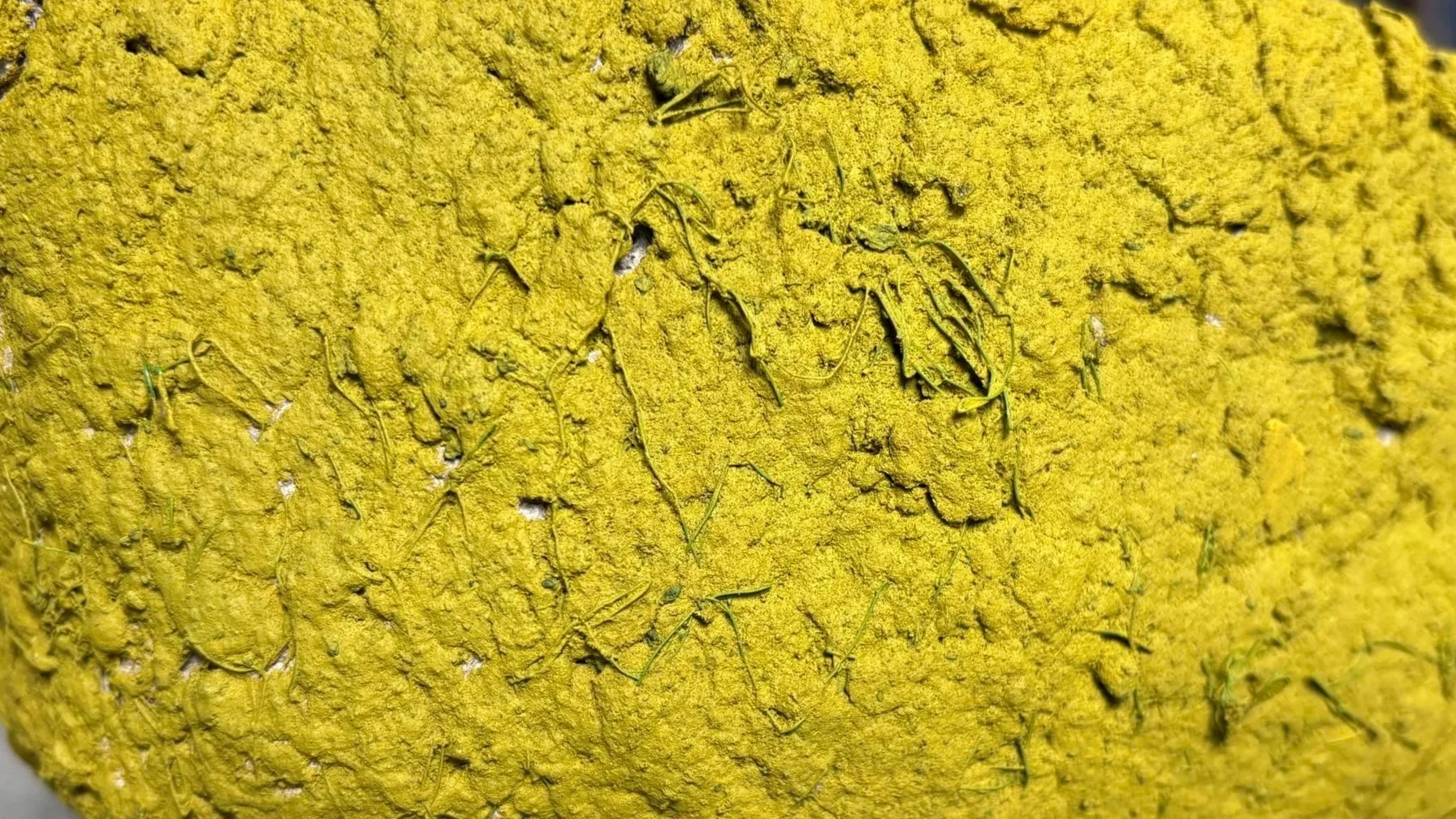

Ash-acrylic coating: a mixture of ash, water, and acrylic paint that forms a matte, mineral-like surface. It can also be used to add texture to paintings.

blend, shape &

let it dry

properties

The mixture dries in the air and tiny crystals of calcium carbonate form in the pulp, working like a mineral glue. Through slow carbonation the dough becomes a light and rigid composite .

Uses post-combustion pellet ash as a mineral filler, giving body and texture to the material.

Reinforced with cellulose fibers from old newspapers, providing strength and structural cohesion.

Improved fire resistance due to its pre-combusted mineral filling.

Composed upcycling common daily waste, with no need for virgin raw materials.

Produced at room temperature, requiring no heat, curing ovens, or energy-intensive processes.

Formed from low-density materials, including porous newspaper pulp and fine ash, resulting in a lightweight and airy structure once dried.

Fully air-dries without chemical setting reactions, reducing retained moisture and simplifying production.

100% recyclable by rehydrating and adding fresh ash or fiber, creating a continuous reuse in a circular process.

performance

Lightweight and low-density

Final dry density ranges from approximately 300–700 kg/m³, significantly lower than conventional concrete (~2,400 kg/m³). This is due to the absence of heavy aggregates and the inclusion of air pockets within the fiber-ash matrix.Thermal and acoustic properties

The ash content offers thermal insulation, while the fibrous cellulose matrix contributes to sound absorption potential, making it suitable for interior panels or acoustic elements.Dimensional stability

The composite maintains its shape without warping under normal indoor humidity levels, even during the drying process.Fire resistance

Part of its filler is already burnt, which makes the material more resistant to fire.

Water permeability

Its fibrous and porous structure enables rapid water drainage, supporting soil permeability, hydrological integration, and applications in flood-resilient design.Biofriendly

In outdoor environments, Askrant can function as a natural planter. Its porous, mineral-rich surface fosters the growth of microorganisms and lichens, supporting small-scale biodiversity.3D printing potential

The material can be explored for 3D printing, enabling customized, scalable, and decentralized production using low-tech or modified extrusion systems.

samples

wip